| |

Production Platform for Device Quality and Cost of Manufacturing Reduction

Streetwise™,

has been deployed in production, globally in a broad variety of

semiconductor device manufacturing operations and fabless design centers

since 2004, and has become the industry’s most advanced Statistical

Post Processing analysis platform for maximizing device quality while at

the same time providing proven multi-flow analysis methodologies for

reducing device manufacturing costs.

|

|

|

| |

|

|

| |

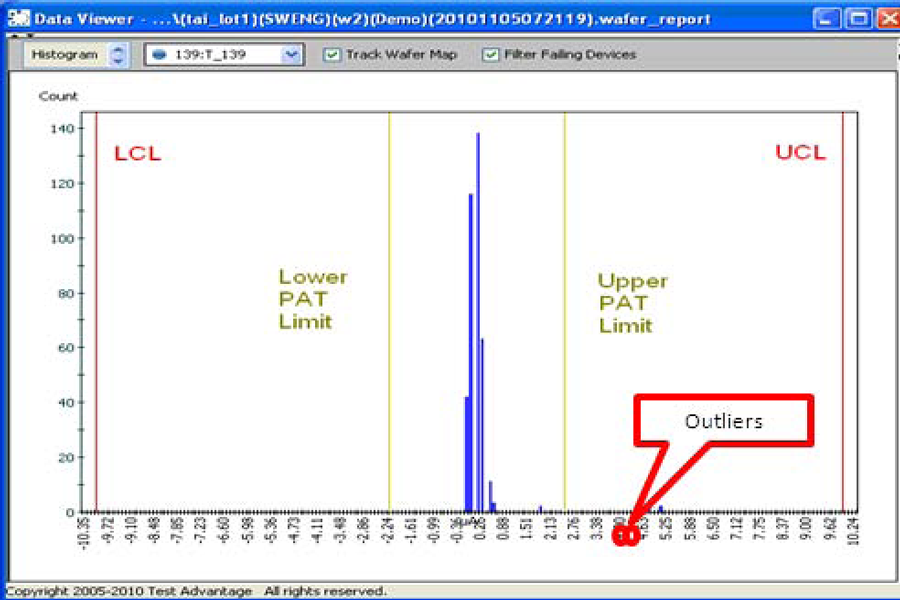

| Streetwise™ supports the use of basic Part Average Testing (PAT) guardbanding methods (see chart 1. below) recommended by the AEC in 1997. (http://www.aecouncil.com) While well understood, these guardbanding methods have recognized limitations and drawbacks. |

Click above to enlarge

|

Chart 1: AEC Q001 guideline for basic distribution N-Sigma outlier detections |

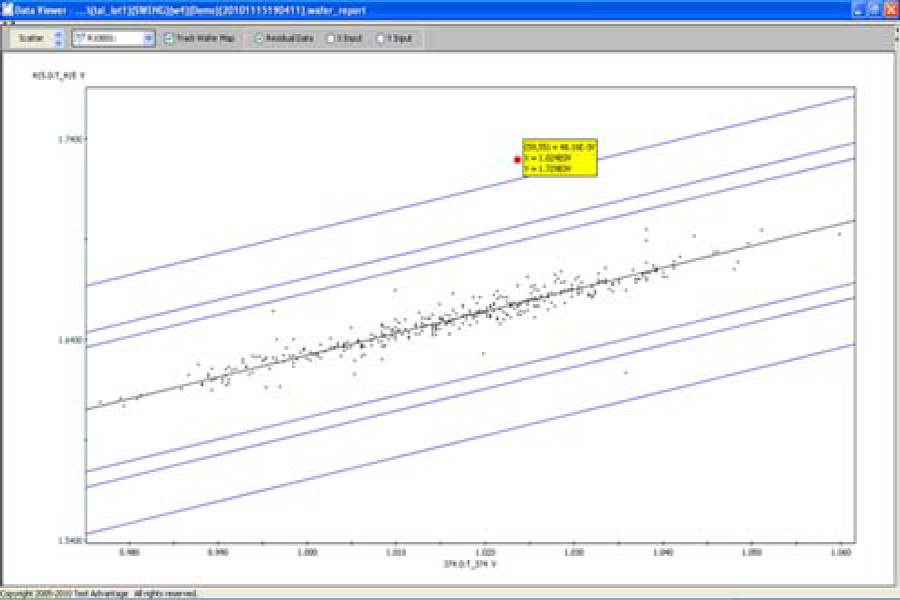

| Moreover, Streetwise™

platform extends the ability to expose device marginalities well beyond

these traditional PAT methodologies, and with more confidence, through

the comprehensive application of Single Variant, Multivariate (NNR,

Regression), Spatial, and Composite analysis methods applied in single

or multiple data flow manufacturing environments. |

Chart 2: Multivariate Hybrid Analysis (NNR)

Click above to enlarge

|

Chart 3: Multivariate Regression Analysis

Click above to enlarge

|

| The increased analysis granularity Streetwise™ uniquely

exposes dramatically extends the opportunity to employ advanced next

generation feed forward adaptive test strategies as outlined in the

latest International Technology Roadmap for Semiconductors (ITRS: http://www.itrs.net).

The industry has recognized that the referenced Adaptive Test

strategies are required as semiconductor device manufacturing cost and

quality demands continue to drive the market forward. |

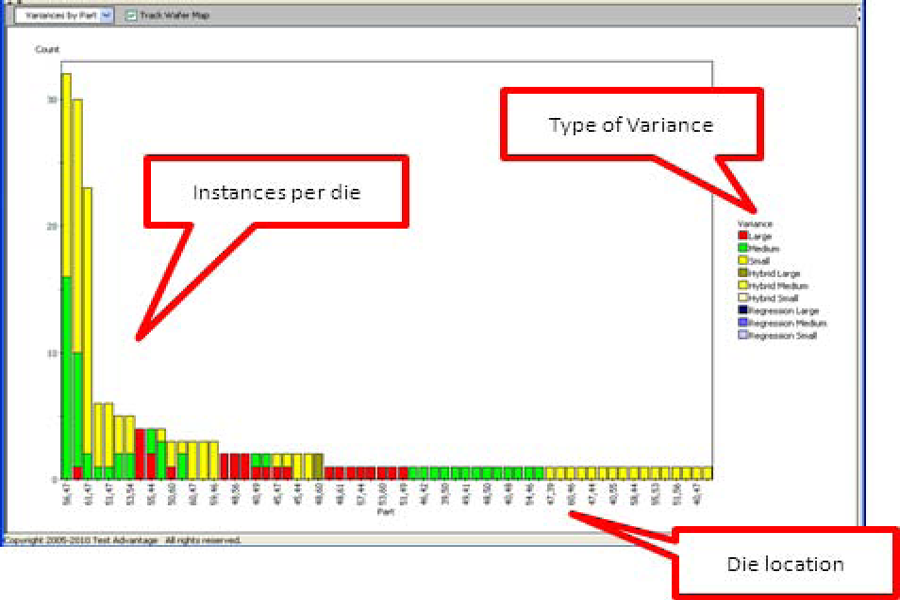

Streetwise™

analysis uniquely identifies device performance variability which

exposes performance marginalities on a per die basis for next process

step or disposition decision. (see chart 4.) |

Click above to enlarge

|

Chart 4: Variance pareto across parametric tests on a per die basis |

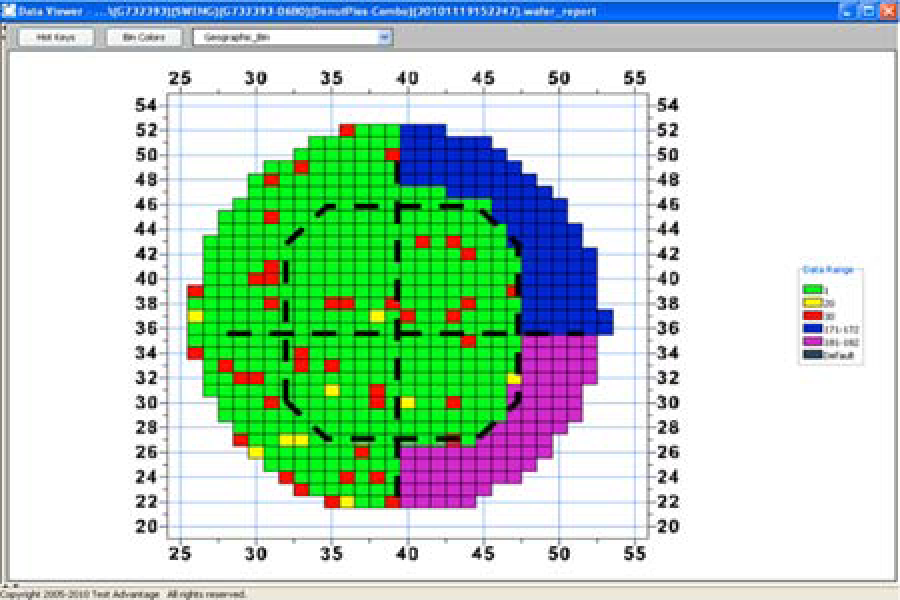

| Streetwise™ uniquely

integrates comprehensive Geographical analysis with Parametric analysis

given the combination of analysis types are considered fundamental in

achieving a high efficiency and effectivity for device disposition

decisions. |

It has been widely

documented within the industry that failed die and/or marginal

performing die adjacencies must be considered in order to properly

disposition target die.

The Streetwise™

analysis architecture leverages its innovative parametric analysis

methods in order to expose geographic based marginalities that expose

not only die related defects, but confirm process or systematic related

defects within identified geographic regions of the wafer. Another

fundamental comprehension of geographical analysis is achieved through

stacked or composite level analysis.

|

Click above to enlarge

Chart 5: Regional geographic spatial analysis

|

Again, well

documented within the industry, specific locations of the wafer may

expose repeatable marginal die locations that may only be exposed

through comprehensive Composite analysis methods.

Streetwise™ geographical

analysis not only leverages Parametric analysis as described above, but

also contains additional sophisticated analysis methods such as:

failure and die marginality clustering, die location exclusion,

proximity analysis, pattern detection, and sub-wafer regional

statistical bin limit detections.

Streetwise™ analysis

technologies have been field proven to apply these next generation

process methodologies today by removing the barriers between wafer fab

parametric data and wafer sort electrical test screenings and final outgoing inspection (see Freescale Press Release for more information).

|

|

|

| |

|

|

| |

Streetwise™ Engineering

is a comprehensive product engineering workbench providing the user

with an easy to use recipe development and validation environment.

Recipe development and validation within the engineering workbench

ensures absolute traceability and revision control when developed

recipes are ultimately uploaded and released to the Streetwise™

Production Tool.

- Application operates on Engineer P.C. or Laptop

- Define Analysis and Binning Strategy

- Validate Analysis results using Data Results Viewer

- Linked to Production for Recipe Management (see recipe mgt chart)

- User Friendly GUI and Editor

- 2D & 3D Wafer view (see wafer view chart)

- Revision controlled recipe editor

- Data trends/histograms/paretos

- Wafer Statistics

|

Recipe Management

Click above to enlarge

2D & 3D Wafer View

Click above to enlarge

|

|

|

| |

|

|

| |

Streetwise™ Production

is a robust production proven 24 X 7 platform that runs the workbench

“recipe” ensuring worry free operation without the necessity of manual

intervention by operators. Integration within manufacturing production

operations is seamless and highly flexible by choosing either TCP/IP

protocol socket connections, file based operations, or Web Services

communications. Data analysis traceability is ensured while recipes and

their corresponding analysis results are defined with four levels of

granularity as Product Family, Recipe ID, Version and History.

- 24/7 hands free production operation

- Scalable software architecture

- Supports Clustered configuration for Automatic failover of application and database

- File, Socket, or Web Services Host Adapters

- Browser based In-Process status interrogation

- Lot results

- Wafer level results

- Automated email notification

- Processing error conditions

- Yield excursion notification

- Revision controlled traceability

|

| |

| |

|

© 2012, 2014, 2021 Test Acuity Solutions, Inc. |

|

|